Indispensable for high purity metals current processing route for products cast from vim furnaces beside the primary vim melting of the so called master.

Vacuum induction melting furnace in india.

3 vacuum induction melting enables a precise adjustment of the alloy composition and melt homogenization of the master alloy.

From induction heating to vacuum induction melting.

High resistance load hrl melting systems.

Owing to the wide experience of this domain we are instrumental in offering pressure vacuum furnace to our clients.

Request a quote inductotherm india pvt.

Vacuum induction melting systems.

Induction systems for vacuum and controlled atmospheres.

Meeting to the customer requirements.

Power window ladle systems.

Ecm technologies is a historic actor in the induction sector in the early 90s ecm technologies and cfei previously saphymo cell both members of the dynathermic group proposed heat treatment installations under vacuum and under controlled atmosphere.

Ladle refining furnaces lrf metal refining with argon oxygen decarburization aod refining systems.

They are built with materials that provide exceptional structural strength and reduced weight key factors in furnaces designed to be moved and poured by hand.

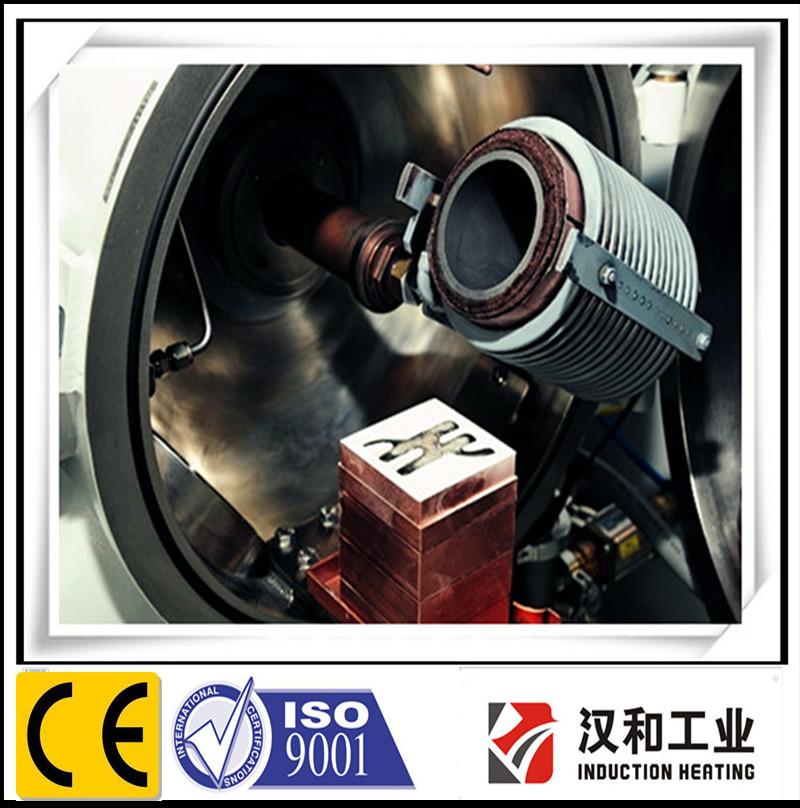

In vim furnace a melting crucible is kept inside a steel shell which is connected to a high speed vacuum system.

Induction melting furnace rs 50 000 piece get latest price we hold expertise in manufacturing and supplying our valued customers a high quality range of induction melting furnace.

It is designed and supplied various size of vacuum furnaces for special applications like vacuum brazing annealing hardening tempering etc.

Continuous induction shell heating facility up to 1250 c during vacuum melting and pouring.

Microtechmake vacuum induction melting vim furnaces can be used for the production of high quality alloys and pure metallic castings for critical aerospace and high technological industrial applications.

High vacuum level up to 1 micron necessary for producing casting free from gaseous defects and inclusions.

Vacuum induction heating graphitization furnace equipment function principle high temperature graphitization furnace is mainly used for battery anode material carbon material structural parts products c c composite material products carbon fiber carbon material carbon fiber rope sintering high temperature graphitization of phosphorus graphite and other graphite materials and others.

Induction power ladle.

Mini melt furnaces are small capacity induction furnaces designed to meet the demanding requirements of investment casters and others.

This is needed for producing thin walled castings.

Inductotherm vacuum induction melting furnaces are designed specifically for operation in high vacuum environments and include vacuum adapted construction methods and the industry s most advanced coil and connector dielectric insulation technologies and procedures.